Cold-chain antivenom delivery in minutes, not hours

Lifesaving antivenom delivery by drone to remote snakebite victims — designed for fast response, reliable cold-chain (2–8°C), and runway-free vertical takeoff and landing.

What we built

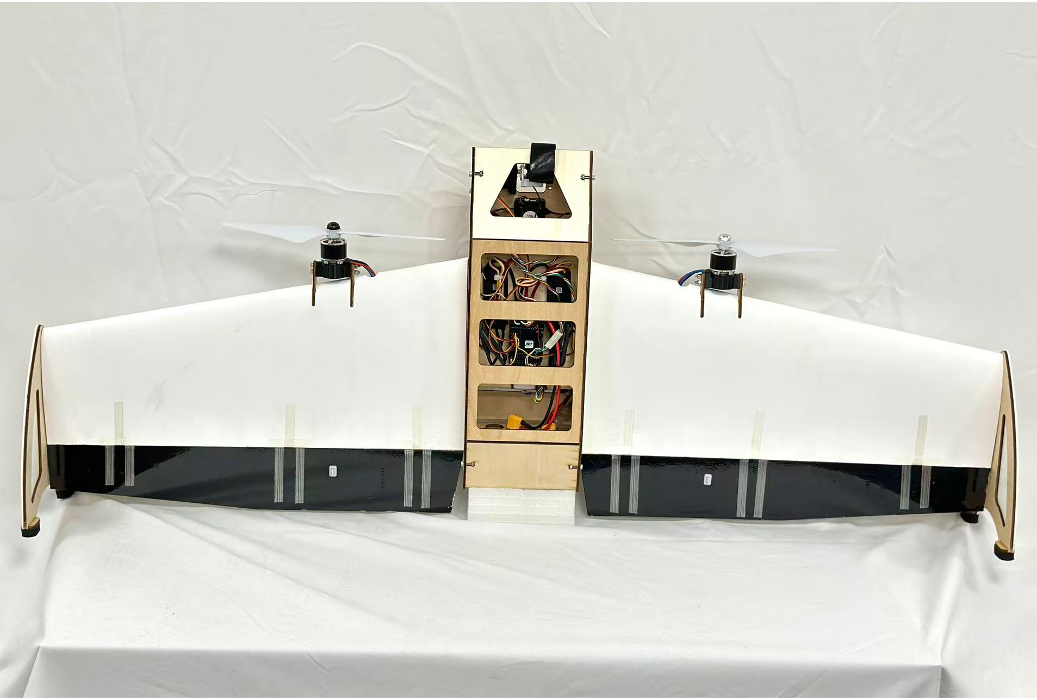

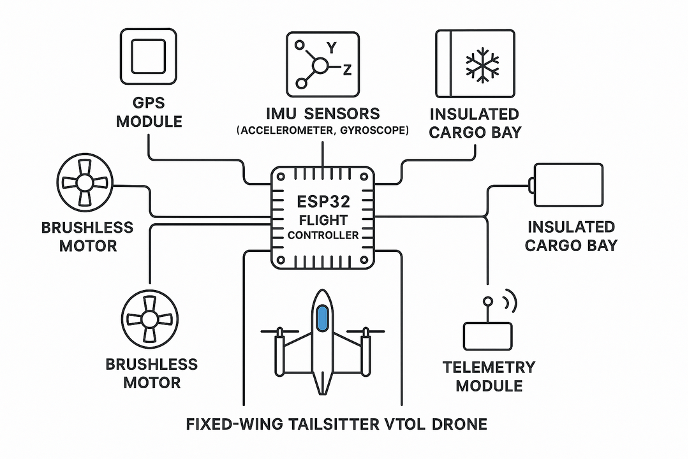

VitalWing is a fixed-wing tailsitter VTOL drone that combines vertical takeoff/landing with efficient fixed-wing cruise. Using passive insulation for the payload bay and autonomous flight control, it aims to deliver antivenom within the critical treatment window.

Quick facts

Use the ↑ and ↓ keys (or PgUp/PgDn) to switch pages, or use the top navigation.

The Problem

Snakebite envenoming is a life-threatening emergency. In many rural regions, antivenom is not available locally. Poor infrastructure and difficult terrain delay delivery, and survival drops sharply if antivenom is not administered within the critical six-hour window.

Target context: remote communities where road speed can be extremely low and time-to-treatment is unpredictable.

Our Solution

VitalWing is a fixed-wing tailsitter VTOL drone built for emergency antivenom delivery. It takes off and lands vertically in confined areas, then transitions into efficient fixed-wing cruise for long-range, high-speed flight — while maintaining cold-chain requirements (2–8°C) using passive insulation.

Key Design Characteristics

- Fast response: targets < 60-minute delivery window for remote missions

- Long-range efficiency: fixed-wing lift enables higher speed and range than multicopters

- Runway-free: VTOL operations for clinics and confined landing zones

- Cold-chain: passive insulation (e.g., PP-board design) supports 2–8°C stability

Innovation

Unique Value Proposition

Compared with slow ground transport and low-range multicopter drones, a tailsitter VTOL combines runway-free landing with high-efficiency fixed-wing cruise — enabling rapid, reliable, and cost-effective delivery to remote locations.

What’s Hard (and Why It Matters)

- Transition stability: smooth VTOL ↔ cruise switching under wind and vibration constraints

- Cold-chain integrity: maintaining 2–8°C without heavy, power-hungry refrigeration

- Repeatable autonomy: reliable waypoint navigation and precision landing

Sustainable Advantage

- Flight control tuning know-how (PID, gain scheduling, transition logic)

- Iterative prototyping across aerodynamics, insulation, and cost

- Accumulated testing data and operational knowledge base

Advantage compounds through flight logs, thermal tests, and real deployment feedback.

Validation & Transition Control Logic

We validate performance with mission-level metrics tied to life-critical delivery: delivery time, temperature stability, autonomous transition success, navigation accuracy, and unit economics.

Validation focuses on stability (wind & transition), cold-chain integrity, and repeatable autonomous operations.

Drone Specifications

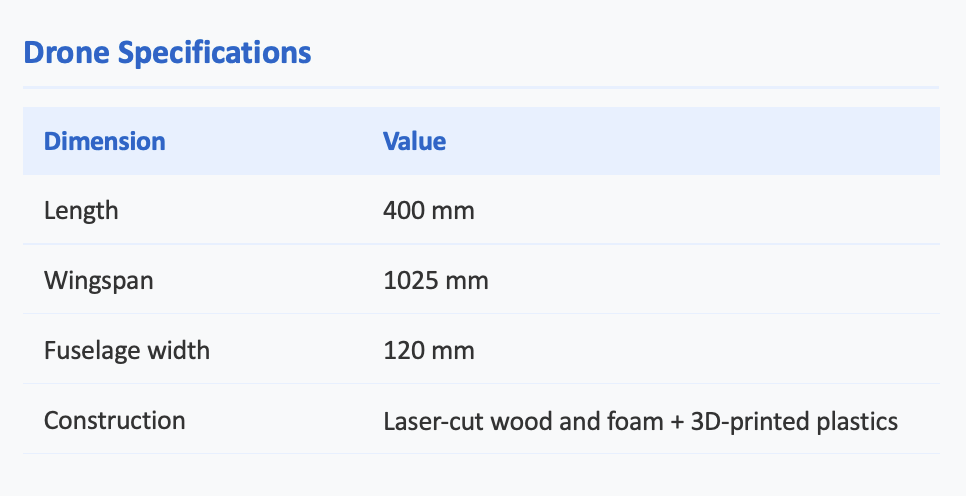

The system is designed around a compact, manufacturable airframe with scalable performance and field-maintainable construction.

Go-to-Market

Customer Segments

- Primary customers: rural hospitals/clinics and health NGOs in snakebite-prevalent regions

- End beneficiaries: remote snakebite victims who face delayed access to antivenom

Channels & Early Adopters

Initial deployment through pilot partnerships with well-equipped regional hospitals and health NGOs in high-incident areas. Demonstration pilots build trust, refine protocols, and generate real-world data for scale-up.

Business Model

Revenue Streams

- Hardware sales: drone system sales (pricing depends on configuration and deployment package)

- Per-mission service: delivery fee per flight mission (pricing depends on region and SLA)

- Maintenance & support: training, spares, and operational support contracts

Cost Targets

- Unit cost target: ≤ ¥2,000

- Operating cost target: ≤ ¥50 per mission

The model combines upfront deployment (hardware) with ongoing operational revenue (missions), supporting sustainable operations.

Impact

By enabling reliable antivenom delivery within the critical window, VitalWing can reduce preventable deaths and strengthen rural healthcare access through scalable aerial logistics.

- Improves time-to-treatment in regions with poor road infrastructure

- Scales via hub placement strategies and repeatable autonomous missions

- Supports global goals to reduce snakebite mortality by improving access to timely treatment

Team

Formed in early 2024, our team came together after learning about a tragic case where a child in Nigeria died in a clinic while waiting for antivenom delivery—highlighting a critical last-mile medical logistics gap. We combined our engineering and product skills to build a tangible solution.

Core roles are structured to cover airframe/aerodynamics, mechanical/robotics execution, and product/market deployment.

Zihan — Airframe & Aerodynamics

Experienced in CAD airfoil modeling and airframe design. Leads aerodynamic optimization, structural layout, and prototype iteration to achieve high-efficiency cruise and stable VTOL behavior.

Focus: airfoil/CAD modeling · airframe design · performance iteration

Jason — Mechanical Engineering & Robotics

Extensive experience in mechanical engineering, especially robotics. Drives mechanical integration, assembly reliability, and field-maintainable design to support repeatable outdoor testing and deployment.

Focus: robotics engineering · mechanical integration · reliability & maintainability

Bella — Marketing & Product Launch

Experienced in marketing and product launch. Leads storytelling, outreach, and partnership-building with health NGOs and public health stakeholders, turning prototype validation into real-world pilot deployments.

Focus: positioning & narrative · outreach · pilots & go-to-market